Multi-Layer and Multi-Pass Welding of Forged Ball Valve Bodies

Multi-Layer and Multi-Pass Welding of Forged Ball Valve Bodies

Sep 20, 2024

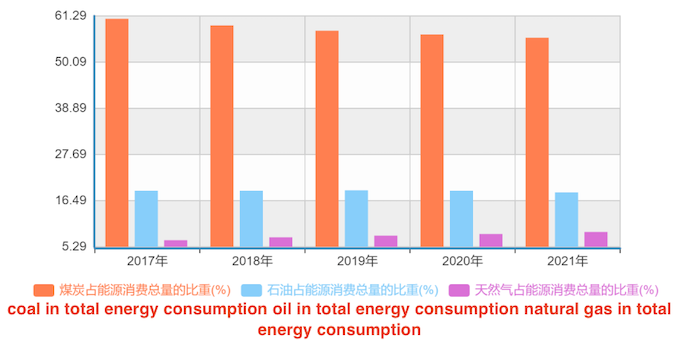

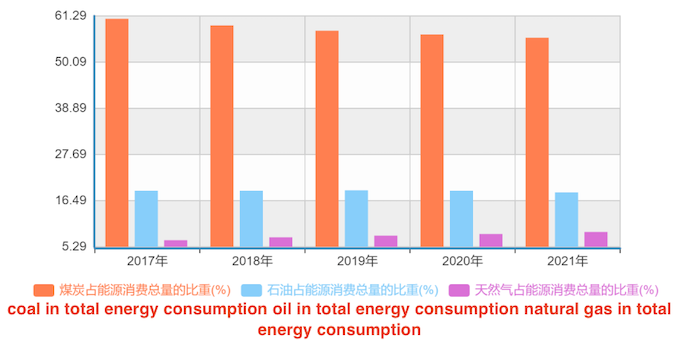

As industries develop, the demand and consumption of energy continue to grow. The extensive use of coal energy can lead to serious environmental problems. Therefore, oil and natural gas have gained national attention due to their clean and efficient advantages. Over the past five years, the proportion of coal in total energy consumption has gradually decreased, while the share of oil and natural gas has increased, as shown in Figure 1.

Figure 1 Proportion of coal, oil, and natural gas in total energy consumption in the past five years

The 2020 '14th Five-Year Plan' energy plan clearly states that China will reach its carbon peak by 2030 and achieve carbon neutrality by 2060. The 14th Five-Year Plan in 2021 marks a critical period for the rapid development of China's oil and gas industry, as well as for valve companies. Driven by factors such as government support for oil and gas infrastructure construction, pipeline companies focusing on pipeline development, and the implementation of smart pipeline to improve efficiency, China's oil and gas pipeline transportation industry is set for substantial growth. Valves are indispensable components in oil and gas pipeline transportation, meaning the valve industry will also face new challenges.

In the manufacture of valve pressure vessels, low-alloy carbon steels such as A105 and A350 LF2 are primarily used. A350 LF2 is a low-temperature steel forging that not only has good mechanical properties but can also be used in low-temperature environments. The lowest service temperature reaches -46°C. A350 LF2 is widely used in the manufacture of low-temperature pressure vessels and pipelines. Welding, a common method for connecting metal structural parts, is primarily used in pressure vessels and oil pipelines. Historically, most pressure vessel and pipeline failures were caused by welded joint failures. Therefore, the strength of pressure vessel welded joints remains a key concern for scholars studying welding processes. During welding, the welding seam metal melts from heat, undergoes plastic strain, and shrinks during cooling. However, the structure of the weld and the material's inherent stiffness hinder shrinkage, resulting in residual stress after welding. In the production of large-diameter forged steel ball valves, welding is the final process. Since the forged ball valve is welded after the sealing ring is assembled, the sealing ring's service temperature typically does not exceed 250°C. Therefore, weld stress after welding cannot be eliminated by heat treatment. The concentration of welding stress promotes the expansion of pre-existing defects in the weld joint into cracks. Weld cracks are the primary cause of welded joint failure. Although large-diameter forged steel ball valves use a multi-layer and multi-pass welding process, subsequent welding seams provide a heat treatment effect on previous welding seams and reduce some stress, the welding seams are annealed and softened under repeated thermal cycles. Therefore, accurately understanding the stress distribution of the welded joint after welding remains essential.

With the advancement of computer technology, welding numerical simulation has emerged as a new research method that is cost-effective and highly efficient. It is widely used to predict the temperature and stress of welded joints. Simulation research on the pressure vessel welding process, particularly the prediction of welding stress distribution, can greatly advance the study of welded joint stress. Current welding finite element simulation technology is primarily based on thermo-elastic-plastic mechanical calculations of materials, overlooking the metallurgical effects during the welding process and the transformation of the welding seam and heat-affected zone structure. For A350 LF2, varying cooling rates result in different phase changes during the welding process. The impact of phase changes on residual stress during welding cannot be overlooked.

In light of this, the project studies the multi-layer and multi-pass welding process of large-diameter forged steel valve bodies in oil and natural gas transportation pipelines, analyzes the mechanical properties and structural morphology of welded joints, develops thermo-metallurgical-mechanical calculation methods and material models considering the metallurgical effects of welding based on thermo-elastic-plastic mechanics, numerically simulates the welding process, predicts the temperature and stress distribution of the weld joint, and experimentally verifies the accuracy of the developed calculation method. The stress evolution of welded joints is simulated and analyzed using thermo-metallurgical-mechanical calculation methods and material models. Additionally, the welding process is optimized through orthogonal experiments.

Figure 1 Proportion of coal, oil, and natural gas in total energy consumption in the past five years

The 2020 '14th Five-Year Plan' energy plan clearly states that China will reach its carbon peak by 2030 and achieve carbon neutrality by 2060. The 14th Five-Year Plan in 2021 marks a critical period for the rapid development of China's oil and gas industry, as well as for valve companies. Driven by factors such as government support for oil and gas infrastructure construction, pipeline companies focusing on pipeline development, and the implementation of smart pipeline to improve efficiency, China's oil and gas pipeline transportation industry is set for substantial growth. Valves are indispensable components in oil and gas pipeline transportation, meaning the valve industry will also face new challenges.

In the manufacture of valve pressure vessels, low-alloy carbon steels such as A105 and A350 LF2 are primarily used. A350 LF2 is a low-temperature steel forging that not only has good mechanical properties but can also be used in low-temperature environments. The lowest service temperature reaches -46°C. A350 LF2 is widely used in the manufacture of low-temperature pressure vessels and pipelines. Welding, a common method for connecting metal structural parts, is primarily used in pressure vessels and oil pipelines. Historically, most pressure vessel and pipeline failures were caused by welded joint failures. Therefore, the strength of pressure vessel welded joints remains a key concern for scholars studying welding processes. During welding, the welding seam metal melts from heat, undergoes plastic strain, and shrinks during cooling. However, the structure of the weld and the material's inherent stiffness hinder shrinkage, resulting in residual stress after welding. In the production of large-diameter forged steel ball valves, welding is the final process. Since the forged ball valve is welded after the sealing ring is assembled, the sealing ring's service temperature typically does not exceed 250°C. Therefore, weld stress after welding cannot be eliminated by heat treatment. The concentration of welding stress promotes the expansion of pre-existing defects in the weld joint into cracks. Weld cracks are the primary cause of welded joint failure. Although large-diameter forged steel ball valves use a multi-layer and multi-pass welding process, subsequent welding seams provide a heat treatment effect on previous welding seams and reduce some stress, the welding seams are annealed and softened under repeated thermal cycles. Therefore, accurately understanding the stress distribution of the welded joint after welding remains essential.

With the advancement of computer technology, welding numerical simulation has emerged as a new research method that is cost-effective and highly efficient. It is widely used to predict the temperature and stress of welded joints. Simulation research on the pressure vessel welding process, particularly the prediction of welding stress distribution, can greatly advance the study of welded joint stress. Current welding finite element simulation technology is primarily based on thermo-elastic-plastic mechanical calculations of materials, overlooking the metallurgical effects during the welding process and the transformation of the welding seam and heat-affected zone structure. For A350 LF2, varying cooling rates result in different phase changes during the welding process. The impact of phase changes on residual stress during welding cannot be overlooked.

In light of this, the project studies the multi-layer and multi-pass welding process of large-diameter forged steel valve bodies in oil and natural gas transportation pipelines, analyzes the mechanical properties and structural morphology of welded joints, develops thermo-metallurgical-mechanical calculation methods and material models considering the metallurgical effects of welding based on thermo-elastic-plastic mechanics, numerically simulates the welding process, predicts the temperature and stress distribution of the weld joint, and experimentally verifies the accuracy of the developed calculation method. The stress evolution of welded joints is simulated and analyzed using thermo-metallurgical-mechanical calculation methods and material models. Additionally, the welding process is optimized through orthogonal experiments.

Next: Research on Multi-layer & Multi-pass Welding Processes Domestically and Internationally

Previous: The Advantages of Forged Steel Valves In High-Pressure Systems

News

About Us

Best Categories

Useful Links